DC Project

Topeka Electric Motor’s first 100% electric vehicle project used a DC motor, which is still the most common type of motor used in conversion projects. It was a learning process for us and ended up going through two distinct phases.

Our starting point for Phase One of the DC project was a 2000 Chevy S10 extended cab 3-door pickup truck. Phase One consisted of a Warp 9™ motor and LogiSystems controller. The battery pack was made up of ten 12-volt lead acid batteries. Additional features include two main 400-amp contactors, an inertia switch, onboard water heat system, working five-speed manual transmissions, vacuum brakes, two battery chargers (one for the 120-volt battery pack and one for the 12-volt DC system), and a functioning alternator for the 12-volt DC system. The range for the original Phase One lead acid battery pack was over 40 miles. However, the lead acid battery pack was a disappointment because it lasted just over one year.

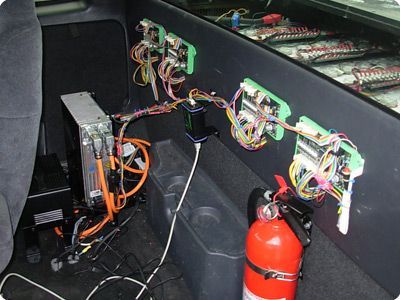

After much consideration, we decided to move beyond a lead acid battery pack and Phase Two consists of a Lithium-Ion battery pack and some new equipment. The new battery pack is made up of 48 Hi-Power brand batteries. The new battery pack takes up approximately 165 volts with 200-amp hours per cell. The new battery pack required a new battery management system and charger. The battery management system is from REAP Systems Ltd and we are using a Brusa charger. A new Soliton 1 controller was installed to handle the higher voltage and amperage. Our range is now up to 100+ miles. The truck has no difficulty achieving highway speeds of 75+ miles per hour. The truck is used on a daily basis for commuting and pickup and delivery in our business.

Summary of Features and Specifications

- Five-speed manual transmission - It shifts just like it did when it was a gas-powered vehicle. Many conversions are clutchless. We believe that a shiftable drivetrain offers many advantages. The drivetrain has a custom-made adaptor to connect the motor to the transmission

- Original 12-volts system was maintained with a functioning alternator for the lights, radio, etc

- Phase One battery packs – ten J185H Trojan batteries 12-volts DC each – hooked in series

- Phase Two battery packs - 48 Hi-Power Life PO4 Lithium-Ion Phosphate batteries, 3.2 VDC nominal voltage. Brusa charger NLG511-SX-130-260 VAC input. REAP Systems BMS with PC tool

- Netbook computer to monitor the BMS

- New Soliton 1 controller

- Water heating system - Water passes through a heater core and warm air is delivered through the existing venting system

- Two main contactors – 400 amp each

- Inertia switch for added safety

IMAGES FROM OUR AC AND DC PROJECTS